Priming Requirements Before Self Leveling Flooring: Preventing Pinholes and Delamination Self leveling systems are designed to create smooth, flat, and durable floor surfaces. However, many flooring failures are not caused by the topping layer itself; they originate at the substrate interface. Pinholes, bubbling, surface craters, and even full delamination are…

Why Polymer Repair Mortar Fails in Structural Repairs: Bond Strength, Substrate Prep, and Curing Errors Structural concrete repairs are not just cosmetic fixes. When beams, slabs, or columns are repaired, the new repair layer must integrate fully with the existing structure. If the repair material fails to bond properly or…

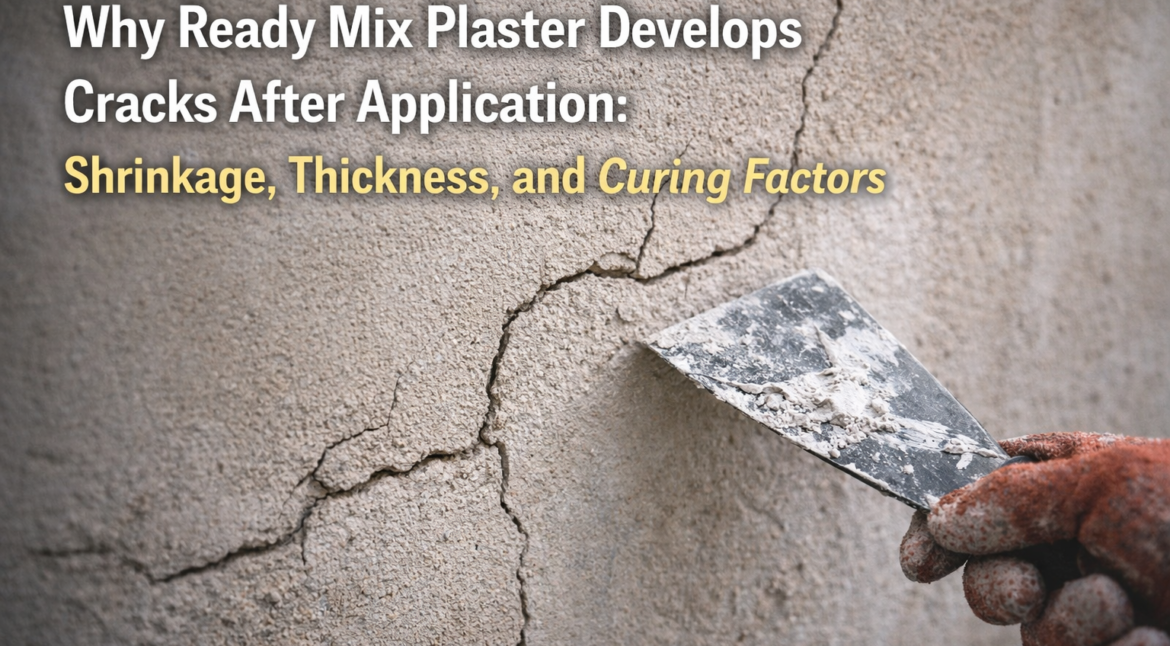

Why Ready Mix Plaster Develops Cracks After Application: Shrinkage, Thickness, and Curing Factors Cracks in plastered walls are one of the most common post-finishing issues in construction. A surface may look smooth immediately after application, but within days or weeks, fine cracks begin to appear. In some cases, they grow…

Epoxy Bonding Agent Selection for Old-to-New Concrete Joints in Load-Bearing Zones Concrete repairs are rarely just about filling a damaged area. In structural zones, the real challenge is ensuring that the new repair concrete behaves as one with the old substrate. If the bond between old and new concrete fails,…

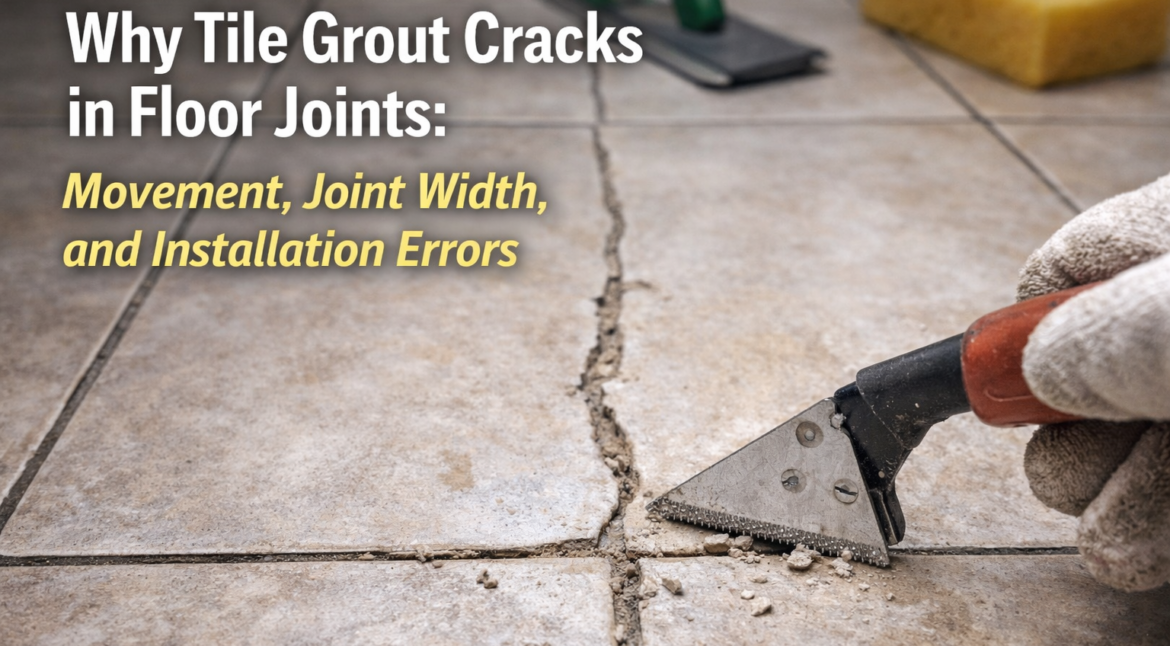

Why Tile Grout Cracks in Floor Joints: Movement, Joint Width, and Installation Errors Cracked grout lines are one of the most common complaints in floor tiling projects. A newly finished surface may look perfect on day one, but after a few weeks or months, grout joints begin to show hairline…

Concrete Admixtures for Precast Elements: Strength Gain, Surface Finish, and Demoulding Speed Precast concrete manufacturing is all about consistency, speed, and quality. Unlike site concrete, precast elements are produced in controlled environments where early strength, surface finish, and faster demoulding directly affect productivity and cost. A small delay in strength…

Why Cementitious Grouts Crack or Shrink After Placement: Mix Design and Curing Factors Grouting looks simple on paper: mix, pour, and allow it to gain strength. But on real sites, grouts often behave differently. Cracks appear around base plates, shrinkage gaps form under machinery foundations, and anchor bolts loosen because…

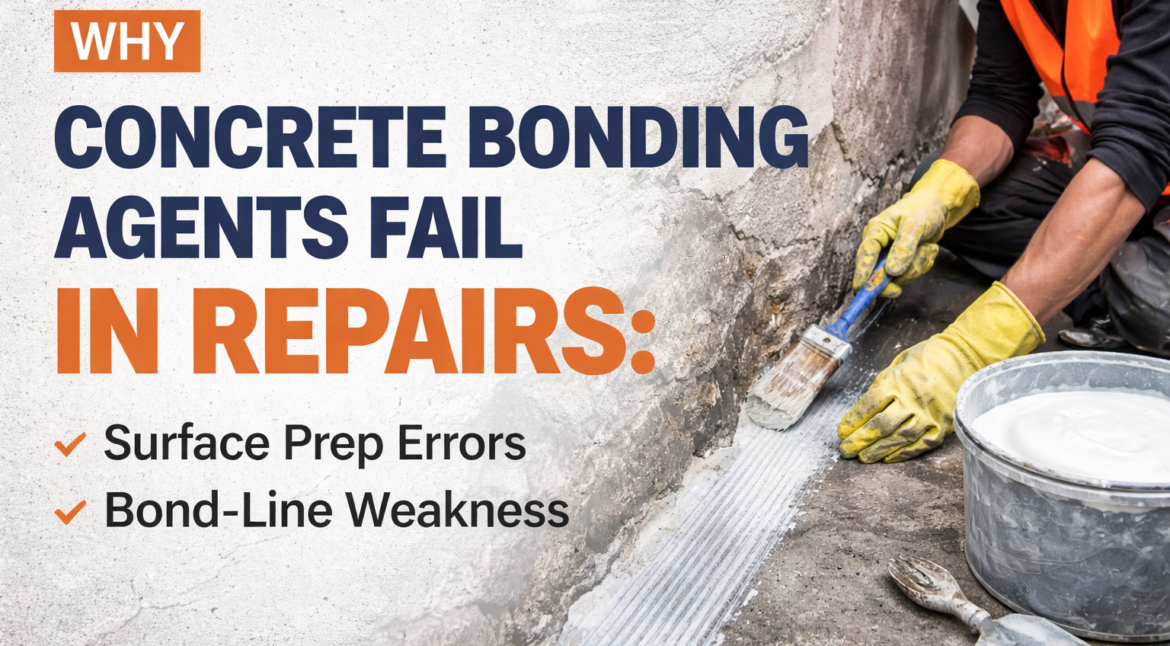

Why Concrete Bonding Agents Fail in Repairs: Surface Prep Errors and Bond-Line Weakness Concrete repairs are expected to restore strength, durability, and service life. Yet on many sites, repair patches debond within months, plaster layers peel off, or new concrete overlays separate from old substrates. In most of these failures,…

Waterproofing Chemical Selection for Roofs, Basements, and Wet Areas: A Practical Comparison Leakage is one of the most expensive construction problems to fix after completion. Roof slabs develop damp patches, basements show seepage lines, and bathrooms or balconies start leaking into lower floors. In most failed projects, waterproofing materials were…

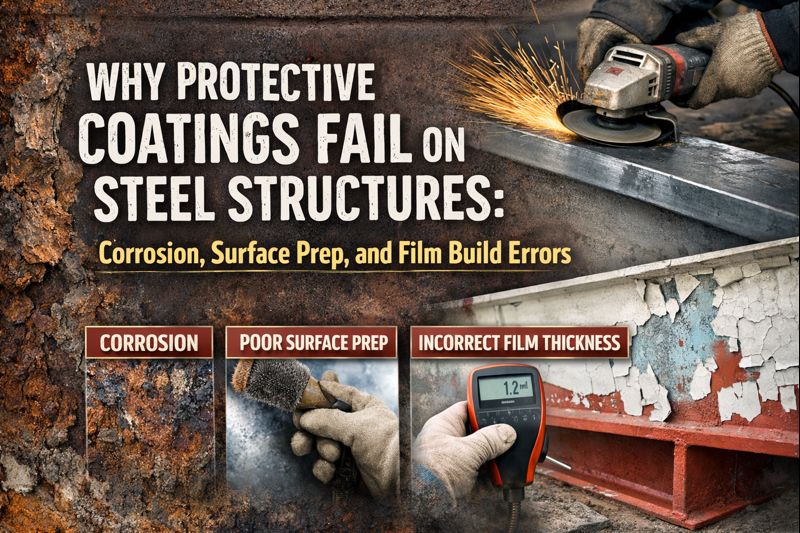

Why Protective Coatings Fail on Steel Structures: Corrosion, Surface Prep, and Film Build Errors Steel structures are designed to serve for decades. Yet in real projects, we often see rust bleeding through paint, coating flakes falling off beams, corroded handrails, and industrial frames requiring repainting far earlier than expected. In…

Chemical Resistance in Epoxy Paints: Why It Matters and How to Select the Best Option In factories, commercial kitchens, basements, swimming pools, and water tanks, paint failure is rarely about appearance. It is about chemical exposure. Oils, acids, detergents, salts, and cleaning agents slowly attack ordinary coatings, leading to peeling,…

When Tile Grout Fails in Wet Areas: Real Causes and Long-Term Fixes Bathrooms with stained joints, balconies showing cracked grout lines, and swimming pools where grout starts washing out are common real-site problems. In most of these cases, the issue is not with the tiles themselves, but with the tile…